Your Product Data Is a Mess

Here’s How PLM Can Fix It

When it comes to managing your product operations, there’s one question that can make or break your efficiency: do you need a Product Lifecycle Management (PLM) system? It’s not a one-size-fits-all solution, and the answer depends on how complex your product ecosystem is and where your pain points lie. If you’re relying on spreadsheets and emails, they might work for now—until they don’t. Let’s explore whether a PLM could be the missing piece in your operations puzzle.

What is a PLM, and What Does It Actually Do?

PLM systems are the nerve centre of product development, acting as the connective tissue between ideas, suppliers, and finished goods. Think of a PLM as the backstage coordinator of your brand’s operations—tracking every thread, cost, and revision before the product hits the market. Here’s what a PLM typically handles:

Supplier communications and costings

Fabric compositions and bills of materials

Sampling iterations and approvals

In essence, a PLM keeps the chaos of product development in check, ensuring every detail is tracked, managed, and optimised for smooth delivery downstream.

Who Actually Needs a PLM?

Not every business needs a PLM. If your product line is simple, your suppliers are few, and your catalog is mostly static, then spreadsheets may be enough. However, if complexity is creeping in—be it through rapid product launches, complex supply chains, or manual errors—a PLM could save you time, money, and frustration.

Here’s when to consider a PLM:

If your business is frequently launching new products or managing seasonal collections, your existing processes may be under strain. You’ll need to track samples, prototypes, and costings across multiple stakeholders, and spreadsheets often fail to keep up with the level of detail required. PLM systems store design iterations, material compositions, and supplier agreements, ensuring product development is structured and documented.

The complexity of handling multiple suppliers can lead to constant back-and-forth communication, slowing down operations. A PLM centralises these interactions, providing a single source of truth for supplier details, purchase order agreements, and product specifications. Instead of sifting through email chains, everything is structured in one place.

Costing and materials management become increasingly intricate as your catalog expands, making it harder to track and optimise production. PLMs track material usage, production lead times, and component costs, feeding this data into ERP systems for real-time financial forecasting and inventory planning. Without a PLM, these processes can become disjointed and error-prone.

Manual errors can creep in, causing costly setbacks that impact efficiency and profitability. PLMs reduce errors by standardising workflows and integrating with PIM systems to ensure enriched product data is carried forward accurately for marketing, e-commerce, and compliance purposes. If these challenges sound familiar, it may be time to explore whether a PLM can streamline your operations and reduce these inefficiencies.

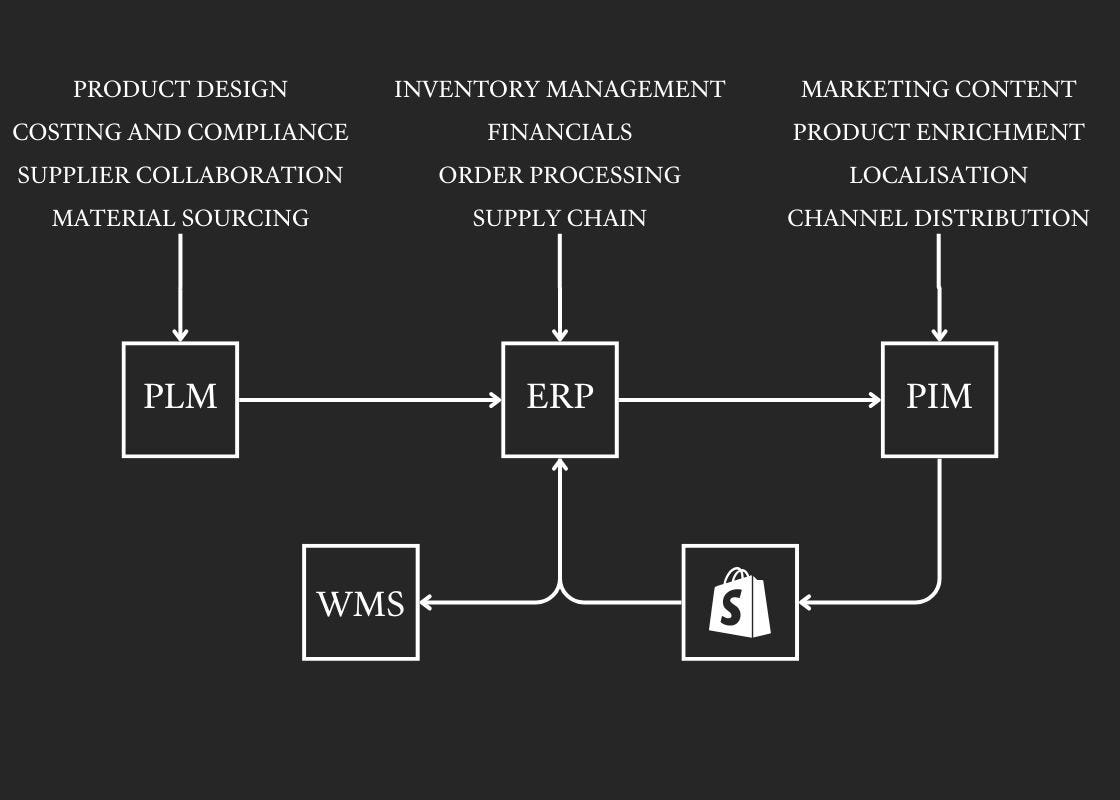

PLM vs. ERP vs. PIM: What’s the Difference?

The tech alphabet soup can be overwhelming, so let’s clarify how PLM compares to other systems:

PLM (Product Lifecycle Management): This is the system that manages product development, tracking every stage from sampling to costings. It ensures all supplier agreements, bills of materials, and initial product data are structured before a product is ready for production.

ERP (Enterprise Resource Planning): This system manages the operational side—handling purchase orders, stock levels, and pricing updates. Once a product is finalised in PLM, it moves into ERP, where financial and logistical processes take over.

PIM (Product Information Management): Once a product is ready to go to market, a PIM ensures all product data is accurate, enriched, and tailored for e-commerce and marketing needs. It pulls structured data from PLM and updates descriptions, attributes, and media for customer-facing platforms.

These systems are complementary rather than interchangeable. For instance, a PLM lays the groundwork by defining product hierarchies and attributes, which are then enriched in the PIM and operationalised in the ERP. Without a PLM, maintaining data consistency across these systems can become a bottleneck.

Can Low-Code or No-Code Tools Replace a PLM?

PLMs are robust, but sometimes it may seem like an overkill solution - especially if there's an element of change management. For smaller brands or businesses with narrow needs, low-code tools like Airtable or Retool can offer a leaner alternative. These platforms can replicate basic PLM functions, such as managing suppliers or tracking samples, without the hefty price tag. Think of it as a half-way-house between spreadsheets and PLM.

However, if you’re managing advanced technical data, high volumes of SKUs, or complex workflows, a dedicated PLM will likely pay off in the long run.

The Future of PLM: Why Regulatory Changes Matter

Upcoming regulations, like Digital Product Passports (DPP), could make PLMs essential for brands. DPP requires extensive product transparency—from sourcing to supplier data—which PLMs are uniquely equipped to handle. Other systems, like ERP or PIM, aren’t designed for the level of granularity that DPP demands.

With stricter compliance requirements on the horizon, a PLM could be the system that ensures your product meets regulatory expectations while maintaining efficiency in production and supply chain management.

Simplifying DPP for independent brands

When talking with brands - especially those without a dedicated sustainability leader - there’s a lot of confusion around DPP and how to execute transparency. As a result, mistakes are being made and, in a lot of cases, no action is being taken because no one brand-side fully understands the challenge.

So, Do You Need a PLM?

Here are the key questions to guide your decision:

Are manual processes causing frequent errors or delays?

Is your product catalog becoming more complex?

Do you frequently develop and launch new products?

Are supplier relationships hard to manage?

Will regulatory changes like DPP impact your operations?

If you’re nodding along to several of these, it might be time to invest in a PLM. That said, if your operations are running smoothly and your needs are straightforward, lightweight tools or even spreadsheets could suffice for now.

Technology is there to serve you, not overcomplicate things. The key is understanding when your processes have outgrown your current tools—and acting before inefficiencies start to cost you.