Your PO Process is Costing You (in More Ways Than One)

How Virtual ‘Containers’ Fix Broken PO Processes

Multi-million pound brands have tens of thousands of sales orders coming through their online stores every day. Yet in spite of this, the purchase order process consists, more often than not, of a repository of manually-updated spreadsheets and never-ending email chains.

Something ain’t right.

POs are critical elements of brand operations. In theory, they should be straightforward - you raise a PO for a certain volume of stock, send it to the supplier, supplier ships the stock, PO is closed off. Bish, bash, bosh.

In reality, POs are messy. So messy that they are costing your business.

In this post, we’re unpacking the delights of PO management:

The problem with POs

The consequences of broken PO processes (time, money & accuracy)

How virtual ‘containers’ clean up the mess of manual POs

The Problem with POs

While every business’ PO process looks different, we’ll share a scenario that we’ve seen time and time again with fashion and new-luxury brands.

Brands will typically raise several POs with multiple suppliers. These POs involve a lot of individual line items. So far, not a big deal, right?

But what often happens is that a 10,000 unit PO gets shipped in 10 x 1,000 unit batches across a full year, rather than in one huge batch. Again, this all sounds pretty manageable in theory.

However, if suppliers make partial shipments on multiple POs–to either consolidate shipping costs, get items ready to sell quickly, or just to break up larger volume orders into more manageable batches–tracking all of these shipments back to their corresponding POs is incredibly complicated. Keep in mind that the same item could appear on multiple POs, making it even harder to track back to their corresponding records.

As a result, partial order shipments have to be repeatedly updated on spreadsheets for months on end, like a never-ending game of Tetris, and the fallout from a broken process like this is staggering (not to mention avoidable, but we’ll get to that later…)

It Costs Time

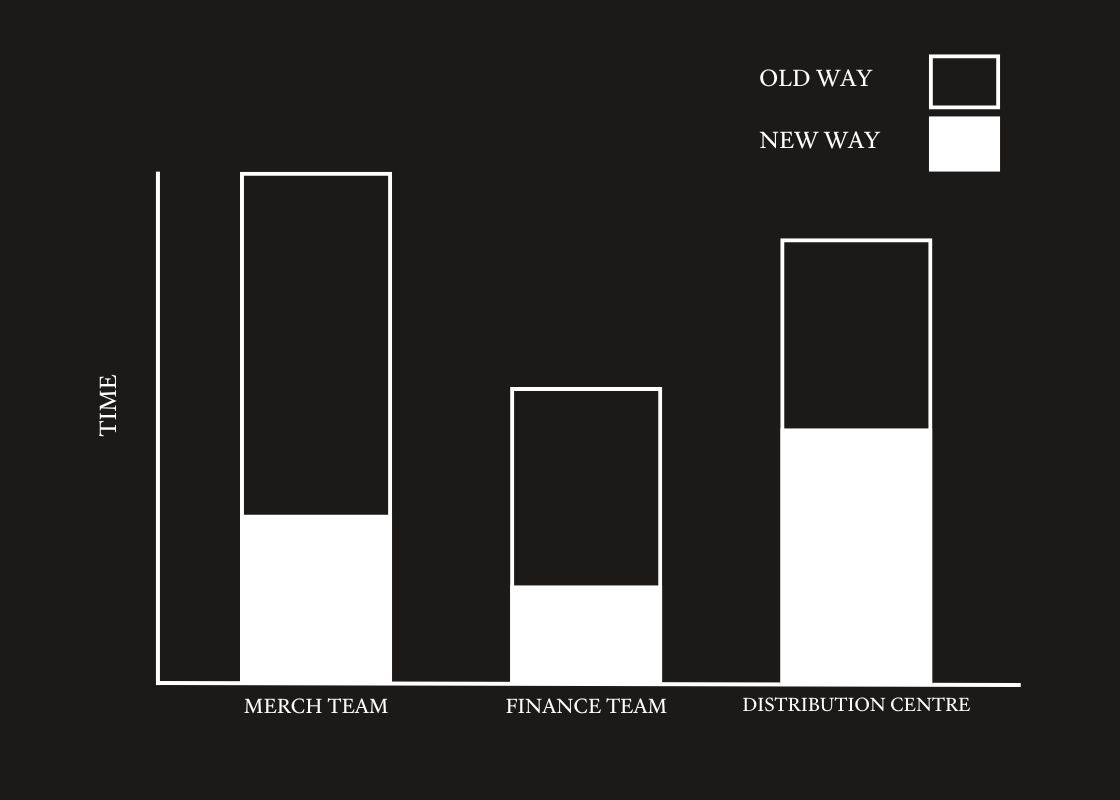

Overly-manual PO flows are a productivity killer for multiple parts of a business:

Merch teams have to do workarounds to split a PO into multiple shipments in order to keep track of each one. Alternatively, they may have to create multiple POs in a granular way to manage and support partial shipments.

Finance teams have to group up multiple POs into one invoice that they might receive from the supplier.

DC teams don’t know the true volume of particular shipments that arrive, and can’t assign resources properly as a result.

It Costs Money

When processes are totally reliant on manual inputting, it leaves an opening for inventory loss. Not to say that suppliers are shady, BUT (and it’s a big but), in the event that a supplier tried to pull the wool over a brand’s eyes and short-change their shipments, they could probably get away with it.

Additionally, you won’t be able to negotiate the best prices for larger volume orders with your suppliers if you struggle to manage the PO process for high volume orders with staggered shipments. This has a direct impact on a brand’s P&L.

Accuracy Takes a Major Hit

Manual PO flows make it impossible for distribution centres to forecast how much time will be needed to receive shipments. In this particular scenario, they should be receiving a PO for 1,000 units, if that’s what’s being sent by the supplier. But what typically happens is that they’re working off a PO for 10,000 units, so the DC can’t accurately forecast the actual volumes of stock that are coming in. As a result, they have to assume that they need resources for 10 hours of work, when in reality, they’re receiving a shipment that could be dealt with in 1 hour.

From an inventory POV, forecasting how much stock to order from suppliers also becomes much harder when POs aren’t 100% up to date or accurate.

How Virtual Containers Clean Up the Mess of Manual PO Processes

Having witnessed the inefficiency of POs for brands first-hand, we developed the concept of virtual containers within a Purchase Order application built in Retool - a solution that systemises the PO process, not only saving time across multiple departments, but also removing room for error.

Here’s how it works

With virtual containers, DCs know exactly what shipment volumes they will receive and can assign resources accordingly. Merch teams no longer have to compare lists from suppliers against lists from the DC because containers enable their system to do this. Finance teams can reconcile orders quicker because they don’t have to break up one big PO into lots of itty bitty ones.

Virtual containers also ensure that your PO versus shipment tracking flow is water tight. You can be sure that you’re getting what you’re ordering from suppliers because containers have filled in the gaps that were otherwise managed with workarounds in spreadsheets.

Manual PO processes might be manageable for small brands that 1) have a limited product catalogue and 2) can comfortably keep track of what’s being ordered, shipped, and stocked. But for larger brands that deal with multiple suppliers, have SKUs in the tens of thousands, and teams whose time could be better spent on something other than solving PO puzzles, it simply doesn’t make good business sense.

Intrigued? Drop us a line at hello@commercethinking.com to find out what’s involved in integrating virtual containers into your PO flows.